胡蝶蘭の知識 - 思いやりのある教育

Production facilities

The cultivation of Phalaenopsis requires steady light control and temperature control, as well as pest and disease control, so the water wall fan greenhouse has been the key production facility. Luminosity should be changed according to the needs of the seedlings: usually from 10,000 lux to 20,000 lux (about 200-400 μmol•m-2•s-1). The temperature is generally controlled below 30~32°C in summer, and is required to maintain above 18~20°C in winter. The mature plants will need to be above 27~28°C in order to avoid premature initial spike. Also, to prevent the intrusion of insect pests, insecticide nets should be installed in the greenhouse.

The USDA-approved Phalaenopsis greenhouse has strict regulations, including greenhouse verification, regular greenhouse inspections, moving in and out operations, and quarantine before exporting. Other countries, such as Canada, have similar regulations.

For details, please contact the Animal and Plant Epidemic Prevention and Quarantine Bureau of the COAG.

Plant treatment and package pre-cooling

Phalaenopsis plants exported by sea to Europe and the United States take approximately 25 to 35 days, and should be kept under shades during transporting. Slightly improper handling may lead to corruption, bleaching of heart and leaves, and cold damage. The most severe cause of plant damage is the yellow leaf disease (Figure 1). The whitening of the heart (Figure 2) will normally return to normal in subsequent cultivation. The cold damage (Figures 3) occurs when the storage temperature is too low for the plants.

To ensure good quality of the storage and transportation, the procedure can be mainly divided into plant treatment and package pre-cooling.

(1) Plant treatment

Plant treatment includes plant selection and drought treatment. Plant selection means selection of good varieties/robust seedlings, and leaf cleaning (such as removing weak seedlings), sphagnum cleaning, as well as insecticidal bactericidal treatment. For the drought treatment, the plants are water-cut for 2 to 4 weeks before packing, depending on the ambient temperature and humidity. The purpose is to reduce the water contained in sphagnum moss by 10~15%. The method of water measurement is to use the Moss moisture meter (Delta-T Devices Media Moisture Meter HH2 Moisture Meter).

The high water content in sphagnum moss will increase the corruption during storage and transportation, the bleaching of the heart and the occurrence of water-soaked tissue in mature leaves, so the drought treatment is rather important.

(2) Package pre-cooling

The packaging will affect the cooling rate and the need for pre-cooling. At present, the packaging used for shipping includes cartons (Figure 4) and trolleys.

Carton: Because the carton is tightly packed in the container, holes on both sides of the carton are not enough. The agricultural experiment institute thus develops a method and drills the holes on the upper and bottom part of the carton, so that the ventilation of the container can pass from the bottom of the carton to the top. It’s been proved that the humidity in the box can be controlled to reduce the damage.

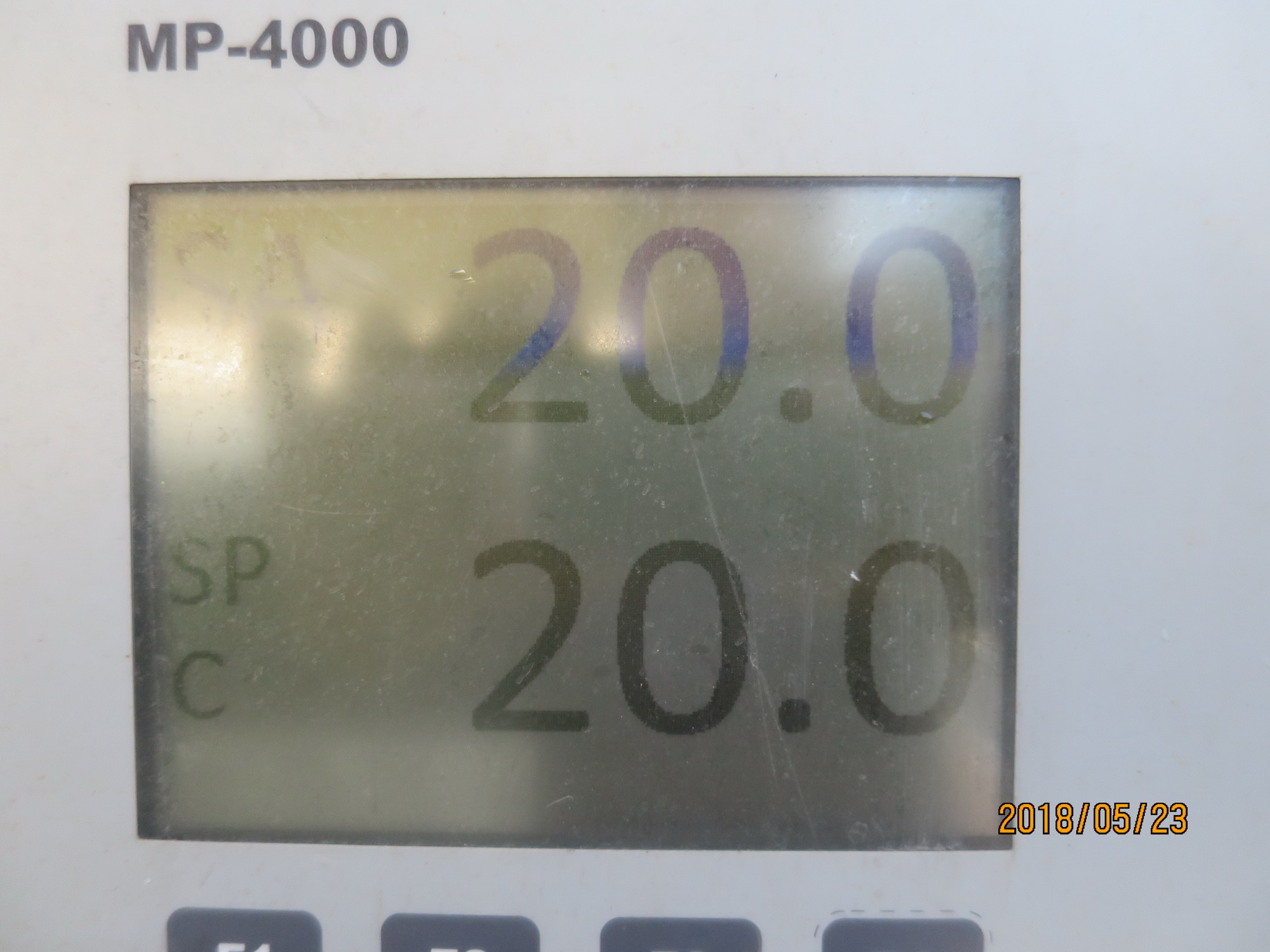

Trolley: The trolley packaging is to place the cartons on the trolley. The upper compartment of the cartons is removed off the cover and only the insect nets are used. This method can make water vapor and reduce corruption. In addition, it is easy to load and unload containers, and it is also convenient for moving between greenhouses and pre-cooling operations. When Phalaenopsis plants are shipped by sea, the container temperature is usually set at 18~20°C. But, the temperature after packing the plants may be higher than 30°C, so pre-cooling before loading the containers makes the temperature dropped to about 20°C, which is extremely helpful for cooling after the container is installed. Pre-cooling is faster in trolleys and it takes about 24 hours to cool in cartons.

(Figure 1) (Figure 2) (Figure 3) (Figure 4)

Transportation

When the Phalaenopsis plants are shipped by containers, and the control of temperature and humidity environment is important.

(1) Temperature Control

The best temperature for Phalaenopsis plant storage and transportation is 18~20°C. Temperature increase will lead to the high percentage of decay (Figure 1), and temperature drop will increase the rate of chilling (Figure 3). The container temperature is stipulated when applying for containers (Figures 5 and 6). However, the actual container temperature may not always be well controlled. There are often temperature fluctuations during the storage and transportation, mainly based on the types of containers and their load (Figure 7). For the maintenance of temperature and humidity of different types of containers, a small temperature and humidity recorder can be placed in the container.

(2) Humidity and ventilation control

The humidity of container-loaded phalaenopsis is often difficult to control and often exceeds 95% RH. Only a few types of containers can dehumidify. Adjusting the size of the container's ventilation (Figure 8), the result on humidity control is usually not obvious, moreover, when the ventilation volume is large, moisture from the outside is sometimes accidentally transmitted to increase the humidity in the container, so the volume should not be too large. About 30~60 CHM (m3/h) will do. The use of packaging with good ventilation can usually reduce losses.

(3) Loading

When containers are delivered to the orchid yard, their condition should be checked and thoroughly cleaned. Moreover, it should be checked whether the container humidity and ventilation volume settings are consistent with the agreed arrangements (Figure 6). It is recommended to load the container in the early morning/at nights to avoid high temperatures. The freezer should not be operated when loading the container, and the height of the items should not exceed the red line set inside the container. Shipment by trolley must be fixed to avoid falling when opening the container.

(Figure 5) (Figure 6) (Figure 7) (Figure 8)